Brass Shuttles

Brass Shuttles Specification

- Product Type

- Brass Shuttle

- Material

- High-grade Brass

- Length

- Varies (Standard approx 120 mm)

- Color

- Golden Brass

- Style

- Industrial Precision

- Thickness

- Approx 6 mm

- Shape

- Rectangular with rounded edges

- Temperature Range

- Up to 200°C

- Quality Standard

- ISO 9001:2015 Certified

- Compatibility

- Suitable for Various Loom Types

- Usage/Application

- Textile Weaving Machines

- Manufacturing Technique

- Precision Machined

- Surface Finish

- Fine Polished

- Weight

- Approx 80 grams

- Corrosion Resistance

- Excellent

- Customisation

- Available On Request

- Packaging Type

- Corrugated Box with Protective Wrapping

Brass Shuttles Trade Information

- Minimum Order Quantity

- 50 Pieces, ,

- Supply Ability

- 1000 Pieces, , Per Day

- Delivery Time

- 4 Days

About Brass Shuttles

Applications: Surface, Plant & Beyond

Our Brass Shuttles offer versatile application, designed for superior performance on various weaving surfaces. Whether employed in large manufacturing plants or smaller workshops, their reliability shines in textile machinery. Further, they adapt to specialised environments, making them invaluable for other industrial textile operations. Their fine polished finish ensures minimal fabric abrasion and maximises operational efficiency across diverse sectors.

Domestic Mar & Export: Ports and Packaging

Main domestic mar includes national distribution across major textile hubs and ensured goods transport via reliable logistics routes. For the export market, FOB at prominent Indian ports like Mumbai and Chennai assures timely global shipment. Packaging details feature a sturdy corrugated box with protective wrapping to safeguard every product. These measures ensure each brass shuttle arrives in pristine condition, enhancing trust for suppliers and buyers alike.

FAQs of Brass Shuttles:

Q: How are brass shuttles used in textile weaving machines?

A: Brass shuttles are inserted into textile weaving machines to guide and carry the weft yarn through the warp, enabling the formation of fabric. Their precise shape and polished surface allow for smooth movement and minimize thread breakage.Q: What is the benefit of the fine polished surface on the brass shuttles?

A: The fine polished surface helps reduce abrasion and friction between the shuttle and fabric, enhancing operational speed and reducing wear on both the shuttle and the woven material.Q: Where are your brass shuttles manufactured and exported from?

A: Our distinguished brass shuttles are manufactured in India, adhering to ISO 9001:2015 standards, and are exported globally via major domestic ports such as Mumbai and Chennai.Q: What is the process for requesting custom sizes or specifications?

A: Clients seeking custom sizes or specifications can contact us directly with their requirements. Our engineering team evaluates and provides tailored solutions to ensure compatibility with a wide range of weaving applications.Q: When is it recommended to use brass shuttles with excellent corrosion resistance?

A: Brass shuttles with excellent corrosion resistance are best used in humid or challenging environments, where textile machinery may be exposed to moisture or chemicals, ensuring long-term performance and reduced maintenance.Q: How does the packaging protect the brass shuttles during transport?

A: Each brass shuttle is securely packaged in a corrugated box with protective wrapping, minimizing shock, scratches, and moisture exposure during domestic mar or international shipping.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

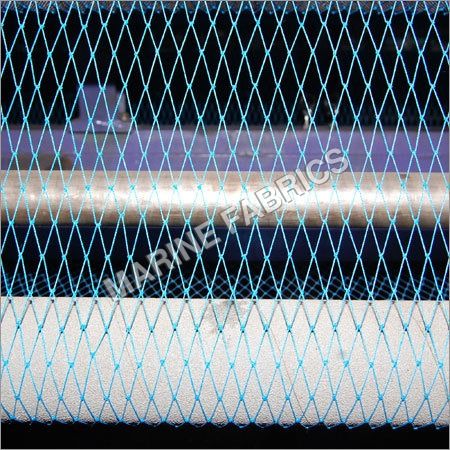

More Products in Fishing Net Making Machines Category

Length Way Stretch Machine

Price Range 1800000.00 - 3500000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Other, Length Way Stretch Machine

Shape : Rectangular Frame

Style : Automatic Mechanical

Length : Customizable up to 20 meters

Side Bottom Harpoon Operator

Price Range 450000.00 - 580000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Other, Side Bottom Harpoon Operator

Shape : Rectangular

Style : Side Bottom Harpoon

Length : Standard/Customizable

Cam Clutch Ratchet

Minimum Order Quantity : 1 Piece

Product Type : Other, Cam Clutch Ratchet

Shape : Cylindrical

Style : Industrial

Length : Standard / Customizable

Upper hook, pinion, washer, eclip

Product Type : Other, Upper hook pinion washer eclip

Shape : Rod and Circular

Style : Industrial

Length : Standard

Send Inquiry

Send Inquiry