Harpoon Left Back View Machine

Harpoon Left Back View Machine Specification

- Product Type

- Harpoon Left Back View Machine

- Knot Type

- Double Knot

- Material

- Stainless Steel & Alloy

- Length

- 1200 mm

- Color

- Silver / Metallic Grey

- Style

- Industrial Mechanical

- Mesh Size

- Customizable

- Depth

- 450 mm

- Thickness

- 8 mm (main frame)

- Shape

- Rectangular

- Power Requirement

- 220V / 50Hz / 1.5kW

Harpoon Left Back View Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10 Pieces Per Day

- Delivery Time

- 1-2 Week

About Harpoon Left Back View Machine

Our organization is a prominent entity in this domain, engrossed in manufacturing, exporting and supplying the best quality Harpoon Left Back View. The machine provided by us is efficiently manufactured using optimum quality components and high-end technology under the strict vigilance of our ingenious professionals in tune with set international standards. Commonly used for weaving fishing nets, this machine in diverse models and technical specifications for our clients to choose from. Clients can purchase this Harpoon Left Back View from us at rock bottom prices.

Features:

- Excellent performance

- Long service life

- Easy to use

- High functionality

Versatile Double Knot Mechanism

Our machines double knot technology enhances structural integrity and product consistency, making it suitable for varied industrial tasks. This feature plays a crucial role in ensuring long-lasting, secure mesh formations, which is particularly valuable in manufacturing environments requiring strength and resilience.

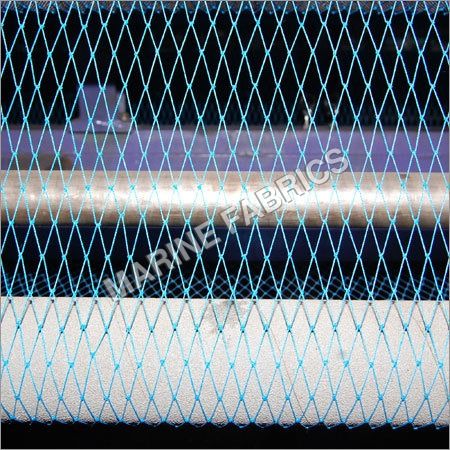

Customizable Mesh for Diverse Applications

The Harpoon Left Back View Machine offers mesh size customization, enabling users to adjust the output according to specific project requirements. Whether you require fine or coarse mesh, the machine provides flexibility to adapt, ensuring suitability for multiple industrial applications.

Robust Stainless Steel and Alloy Construction

Built using high-grade stainless steel and alloy, this machine delivers superior corrosion resistance and extended service life. The sturdy 8 mm thick main frame provides the necessary support for continuous operation, even in demanding manufacturing settings.

FAQs of Harpoon Left Back View Machine:

Q: How does the double knot mechanism in this machine benefit industrial applications?

A: The double knot feature reinforces the mesh structure, increasing its durability and strength. This is especially beneficial for industries requiring secure and stable mesh formations, as it ensures reliability and reduces the risk of product failure under stress.Q: What materials are used in constructing the Harpoon Left Back View Machine?

A: This machine is manufactured using high-quality stainless steel and alloy, which provides excellent resistance to corrosion and wear, ensuring long-lasting performance even in rigorous industrial environments.Q: When should you consider customizing the mesh size?

A: You should customize the mesh size when your application requires specific filtration, protection, or separation standards. Customization enables the machine to accommodate unique project needs, improving efficiency and effectiveness in various use cases.Q: Where is the Harpoon Left Back View Machine commonly utilized?

A: The machine is widely used in manufacturing sectors, particularly in facilities that require robust mesh production, such as construction, fencing, or industrial filtration. Its adaptability makes it suitable for both small-scale workshops and large-scale factories.Q: What is the process for operating this machine effectively?

A: To operate, ensure the machine is connected to a 220V / 50Hz power supply and set the desired mesh size. Once in operation, regularly monitor the machine and perform routine maintenance checks to uphold optimum performance and safety standards.Q: How does the power requirement of 1.5kW contribute to efficient usage?

A: With a power requirement of only 1.5kW, the machine is energy-efficient without sacrificing performance. This allows for cost-saving over long periods of use, supporting sustainable operations while maintaining productivity.Q: What are the benefits of the machines stainless steel and alloy construction in industrial settings?

A: The robust construction offers exceptional durability, resists corrosion, and minimizes maintenance needs, providing consistent performance and reducing downtime, which is essential for maintaining workflow in industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Fishing Net Making Machines Category

Double Knot Fishing Net Machine

Price 4500000 INR / Set

Minimum Order Quantity : 1 Piece

Length : Customizable

Style : Mechanical/Industrial

Color : Blue/Light Grey

Side Bottom Harpoon Operator

Price Range 450000.00 - 580000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Length : Standard/Customizable

Style : Side Bottom Harpoon

Color : Green

Fishing Net Making Machine Model Mint

Price Range 40000.00 - 80000.00 INR

Minimum Order Quantity : 1 Piece

Length : Customized

Style : Model Mint

Color : Mint Green

Brass Shuttles

Price Range 1200.00 - 4000.00 INR / Piece

Minimum Order Quantity : 50 Pieces, ,

Length : Varies (Standard approx 120 mm)

Style : Industrial Precision

Color : Golden Brass

Send Inquiry

Send Inquiry